- upload bom file

- +86 0755-82770375

- sales@bomkitting.com

Oxidation of Electronic Components: Manifestations and Remedies

I. Typical Manifestations

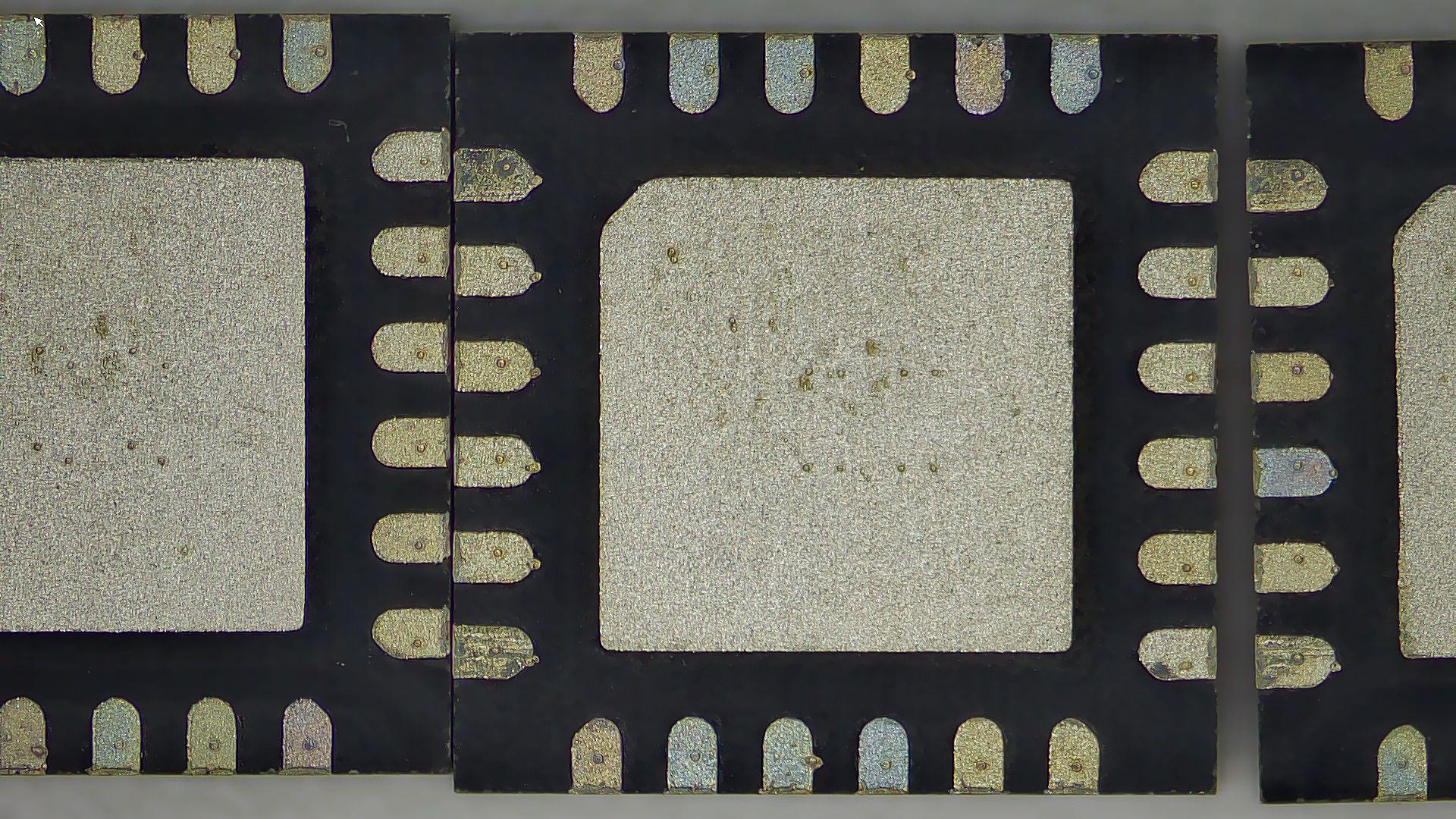

Visual Indicators

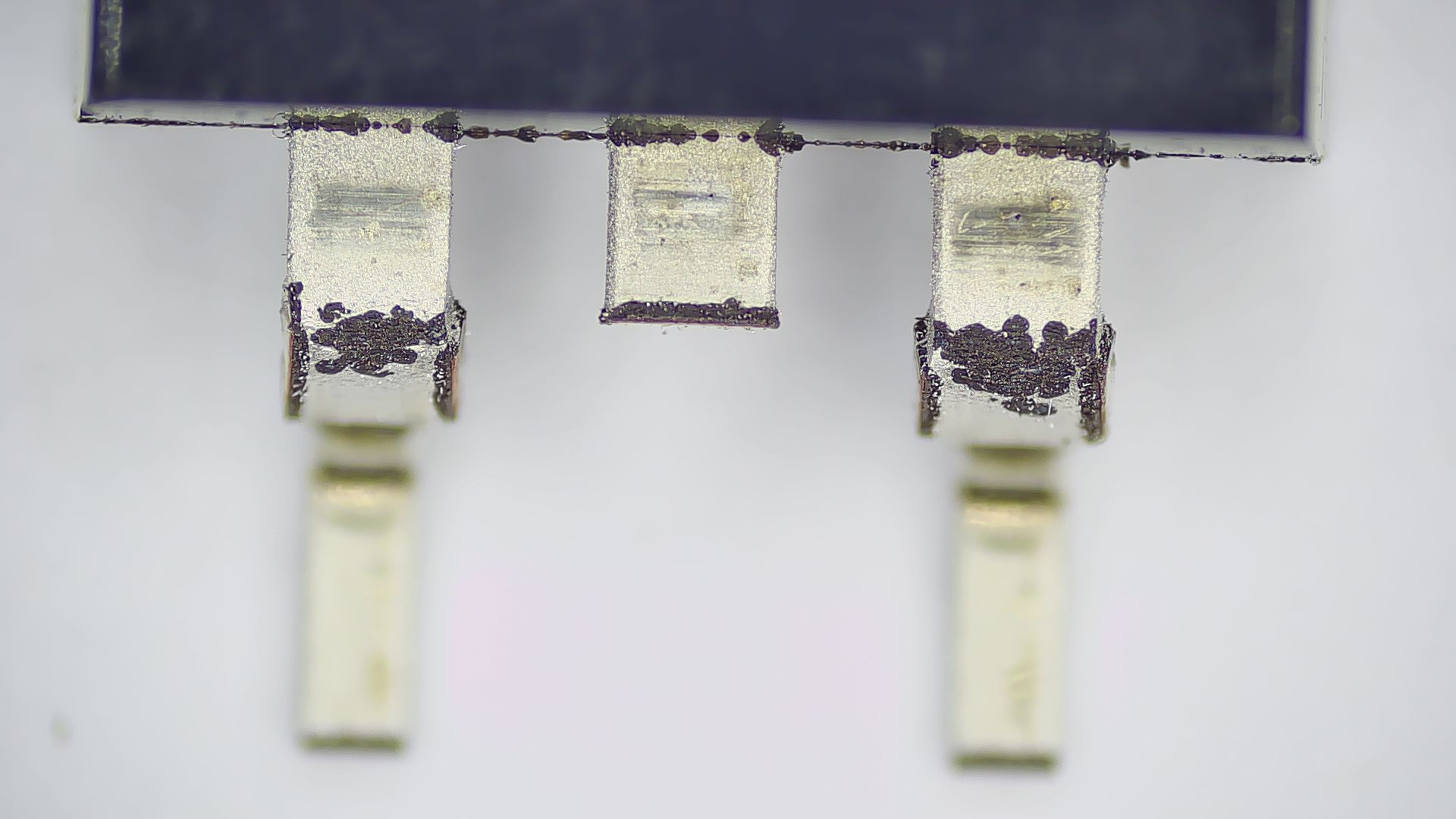

• Leads or solder balls lose their metallic sheen, appearing dull, gray or speckled with black spots.

• Surfaces become pitted, rough or discontinuous.

Solderability Degradation

• Under low-power magnification, solder refuses to wet the leads, resulting in non-wetting, dewetting or localized voids.

• Per GJB360B solder-iron test: tinned area < 95 % or concentrated defects classify the part as oxidized.

Electrical Drift (common in long-stored ICs)

• Contact resistance rises, leakage current increases, and in extreme cases functionality is lost.

II. Severity Levels and Corresponding Actions

Level Characteristics Recommended Action

Level 0 (Acceptable) Bright, contamination-free surface Use as-is

Level 1 (Mild) Slight graying, localized dulling May be used directly; light de-oxidation if process demands are high

Level 2 (Obvious) Large-area graying, reduced solderability Mandatory de-oxidation (re-tinning, chemical cleaning, etc.)

Level 3 (Severe) Blackened, heavily pitted, total luster loss Scrap or re-plate / re-ball

III. Common De-Oxidation Methods

Physical-Mechanical

• Fine abrasive paper or eraser: gently rub along the lead, then clean with alcohol and re-tin. Suitable only for coarse-pitch components.

• Blade or file: removes oxide but risks damaging the plating; not recommended for precision devices.

Re-Tinning

• Manual: 300 ± 20 °C iron, dip in rosin, quick drag-solder; cool one side before the other.

• Solder pot: batch-immerse leads in 245 ± 2 °C solder for 2–3 s; efficient, requires continual dross removal.

• Precautions:

– Use heat-sink clips or pre-heat for heat-sensitive devices (glass diodes, tantalum capacitors).

– Employ dedicated fixtures for BGAs/QFNs to prevent ball deformation.

Chemical-Flux Method

• Mix: ALPHA FLUX A88 or CSF898 flux : rosin = 3 : 1 by mass.

• Steps:

① Brush the mixture evenly over the leads.

② Bake at 125 ± 3 °C for 2–3 min.

③ Rinse with anhydrous ethanol and air-dry.

④ Post-bake at 115 °C for 24 h to remove moisture.

• Advantages: ideal for fine-pitch ≤ 0.5 mm parts, no bridging, no mechanical stress.

Chemical Soak

• Light oxidation: proprietary de-oxidizing solution for 5–10 s → dry.

• Heavy blackening: strip plating → re-plate (leaded devices) or re-ball (BGAs).

Protection & Prevention

• Storage: vacuum bags + desiccant + nitrogen cabinet, RH ≤ 30 %; once opened, use promptly.

• Handling: keep in ESD/moisture-proof boxes to minimize exposure time.

• Process: implement AOI and solderability spot checks before SMT to prevent oxidized components from entering production.

IV. Workflow in Brief

“Look → Judge → Choose → Act → Verify”

Look: screen visually with 5–10× loupe or microscope.

Judge: classify per table or run solderability test.

Choose: select mechanical, re-tinning or chemical method based on package type, oxidation level and volume.

Act: strictly control temperature, time and ESD; run small samples first if necessary.

Verify: after de-oxidation, sample for solderability, X-ray and functional tests to close the quality loop.